Reactor: Screening reactor configurations and design concepts for coupled regeneration-methanation

This work package evaluates potential reactor design concepts and operation for integrated regeneration-methanation, and provide criteria for the process integration in the system model and for the development of suitable materials.

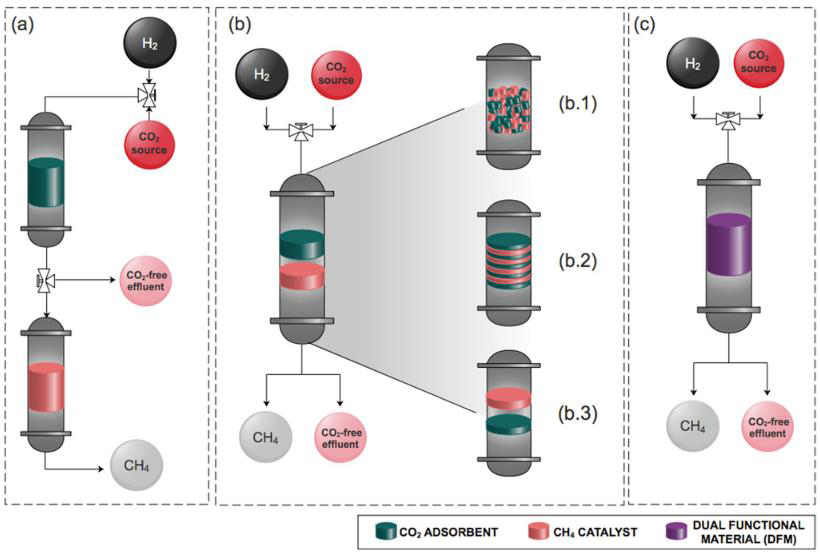

The complexity of the coupled regeneration-methanation reactions has implications for the reactor selection and operation. Heat transport from the exothermic methanation reaction to the endothermic CO2 desorption is challenging, and solutions are needed. The sorbent becomes (un)saturated during sorption-desorption cycles. The dynamic reactor operation must be taken into account when screening for potential reactor configurations. The dynamic character is aggravated by the energy system dynamics. If CO2 capture solely takes place at the gas-fired powerplants, which mainly operate when RES capacity is insufficient to deliver peak load, then CO2 and electrolytic (green) hydrogen are not produced at the same time. Storage and heat integration will have to be carefully managed and this will complicate reactor operation. For industries with high-temperature processes, CO2 emissions are continuous, even when green hydrogen is also produced. UCL will evaluate the applicability of different reactor types against targets set by the system model.

To resolve the reactor design issues, various aspects must be addressed, such as: whether the reactor requires stationary or non-stationary operation, the possible gas and solids residence times, and management of heat integration. These aspects will be investigated for fixed-beds, moving bed and fluidized bed type reactors. These considered reactor types are well-known and are used in a variety of industrial processes. The potential reactor concepts will be evaluated initially using standard reactor models, and as the methodology is refined throughout the project, advanced multiscale reactor models will be developed. Structured reactors are also studied as a potential reactor concept, and their modeling have been extensively studied in the group of Prof. De Wilde.

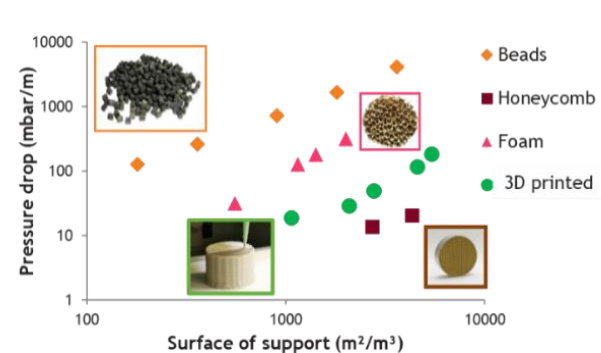

Mg-based sorbents are usually synthesized as fine powders and cannot be directly used in reactors, which is why structuring is required. Structuring can involve the shaping of powders into larger granules. Packed beds of beads or granules suffer predominantly from a high pressure drop and high heat- and mass transfer resistance when higher throughputs are required, leading to lower productivity, a low recovery and higher power consumption. These challenges can be overcome by using monolithic structures that allow high air flows to contact the sorbent with minimal energy loss (i.e. low pressure drop). Structured reactors intensify mass- and heat transfer by enabling fast and energy-efficient sorption and catalysis. Shaping of powders into hierarchically porous structures is one of the core research activities in the Coating and Shaping Technologies Group at VITO, and the strong collaboration between VITO and UCL in this work package is hence beneficial.

Research questions:

- Can the targets developed in the system scope be achieved by new reactor concepts and efficient heat integration?

- How can the sorbent and catalyst shaped into structured materials to limit heat- and mass transfer limitations? What is the impact of the shaping on the sorption, catalytic performance and mechanical stability at operational conditions?

- Can we achieve the technical and economic criteria that resulted from the concept study?

Tasks

T3.1 Screening of potential reactor concepts using standard reactor models

T3.2 Shaping of the selected sorbent & catalyst into structured materials for optimal mass- and heat-transfer

T3.3 Detailed multiscale modeling of selected reactor concept